Prototyping Permeability

Floods brought on by severe storms are increasing in frequency and magnitude. These extreme events are made worse by our urban environment being plastered with impervious surfaces like concrete and asphalt parking lots, roads, and sidewalks. Pervious paving has come a long way, but the market still lacks aesthetically-pleasing yet affordable systems that designers can embrace and cities can actually afford.

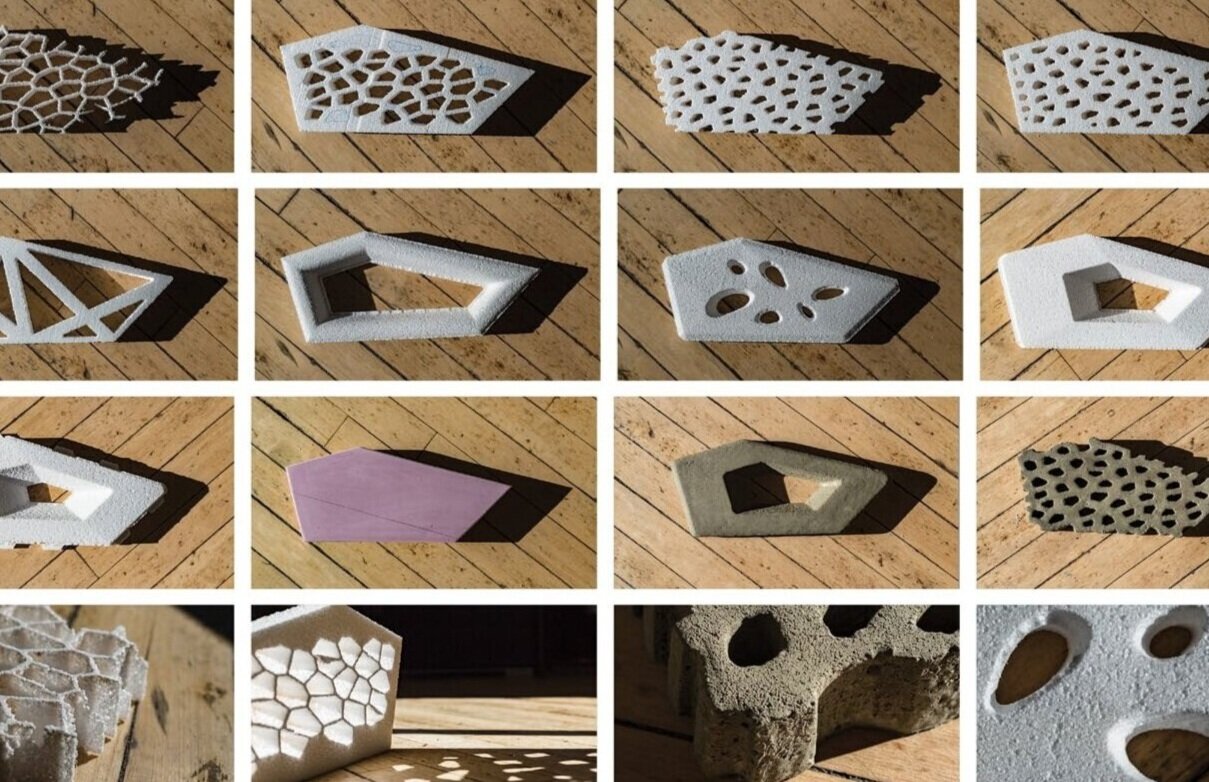

In 2017, Courtney Goode was awarded a highly-coveted design research grant from Sasaki Associates for $10,000. Over the course of 6 months, she worked closely with a team of advisors and collaborators to investigate how leading-edge parametric software and digital fabrication tools might support the design process and help develop a flexible, kit-of-parts that was highly permeable, design-forward, durable, and affordable. The project drew on a mix of old and new practices. Emerging software and technologies like parametric modeling and digital fabrication were balanced with tactile material tests, rigorous craft, and a series of hands-on workshops that aimed to build community through making.

The team developed a permeable paving system made of 9 unique porous pavers that combine to create endless configurations of visual patterns, porosity gradients, integration with planting beds, and seamless transitions from porous to non-porous, smooth walking surfaces in an effort to achieve ADA compliance.

This system not only prevents surface runoff, but it recharges groundwater supply, decreases contamination of waterways, and redirects water into adjacent planting areas, and provides a striking paving pattern that is flexible enough for designers to make it their own.

This research project was built as a walkway at the Sasaki corporate offices in Watertown, MA in 2017. It was featured in the December 2018 issue of Landscape Architecture Magazine and presented at the National ASLA Conference in Los Angeles in 2018.

Work completed while at Sasaki.

Floods brought on by severe storms are increasing in frequency and magnitude. These extreme events are made worse by our urban environment being plastered with impervious surfaces like concrete and asphalt parking lots, roads, and sidewalks. Pervious paving has come a long way, but the market still lacks aesthetically-pleasing yet affordable systems that designers can embrace and cities can actually afford.

In 2017, Courtney Goode was awarded a highly-coveted design research grant from Sasaki Associates for $10,000. Over the course of 6 months, she worked closely with a team of advisors and collaborators to investigate how leading-edge parametric software and digital fabrication tools might support the design process and help develop a flexible, kit-of-parts that was highly permeable, design-forward, durable, and affordable. The project drew on a mix of old and new practices. Emerging software and technologies like parametric modeling and digital fabrication were balanced with tactile material tests, rigorous craft, and a series of hands-on workshops that aimed to build community through making.

The team developed a permeable paving system made of 9 unique porous pavers that combine to create endless configurations of visual patterns, porosity gradients, integration with planting beds, and seamless transitions from porous to non-porous, smooth walking surfaces in an effort to achieve ADA compliance.

This system not only prevents surface runoff, but it recharges groundwater supply, decreases contamination of waterways, and redirects water into adjacent planting areas, and provides a striking paving pattern that is flexible enough for designers to make it their own.

This research project was built as a walkway at the Sasaki corporate offices in Watertown, MA in 2017. It was featured in the December 2018 issue of Landscape Architecture Magazine and presented at the National ASLA Conference in Los Angeles in 2018.

Work completed while at Sasaki.